Paver Installation

Not all paver installations are created equal. At Southern Crafted Hardscape’s we believe in paving surfaces with not only style and beauty but also in a manner that will last a lifetime. We attribute this to our commitment to exceed standards and never cut corners.

We’re not just talk.

We stand behind our work and our clients. Offering a warranty that would strike panic in “cowboy” contractors, if they were held to the same degree. We offer a minimum five year transferable warranty on pavers installations. In addition to this we only install reputable pavers from manufactures like Unilock that offer a lifetime warranty on their products. We also believe in transparency here at SCH. Below we have outlined exactly how we go about installing pavers.

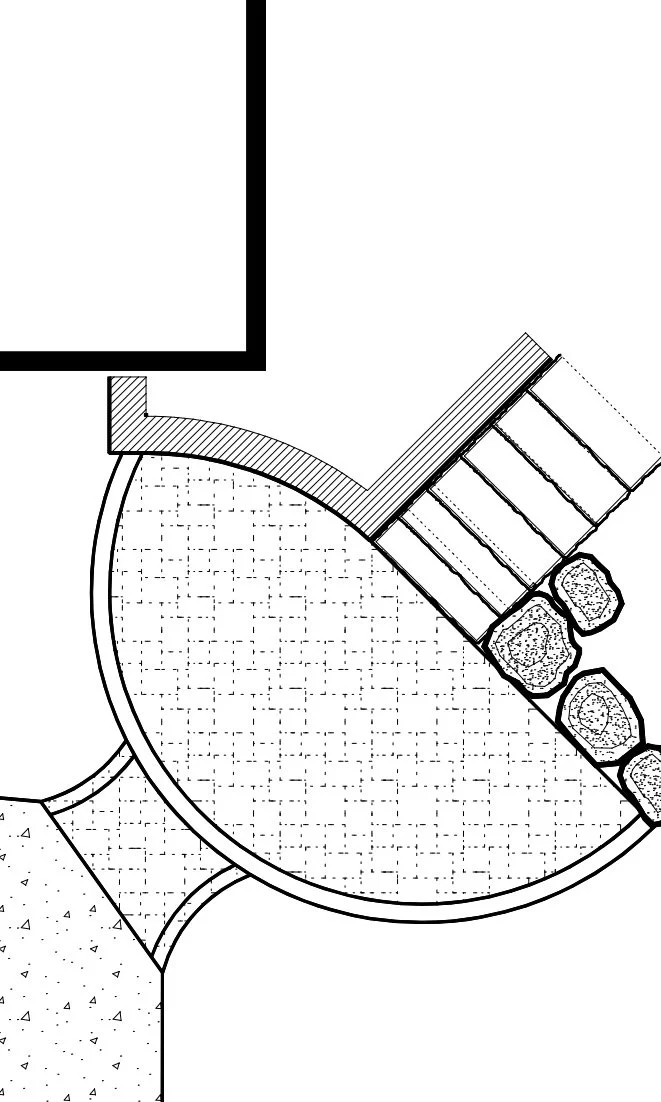

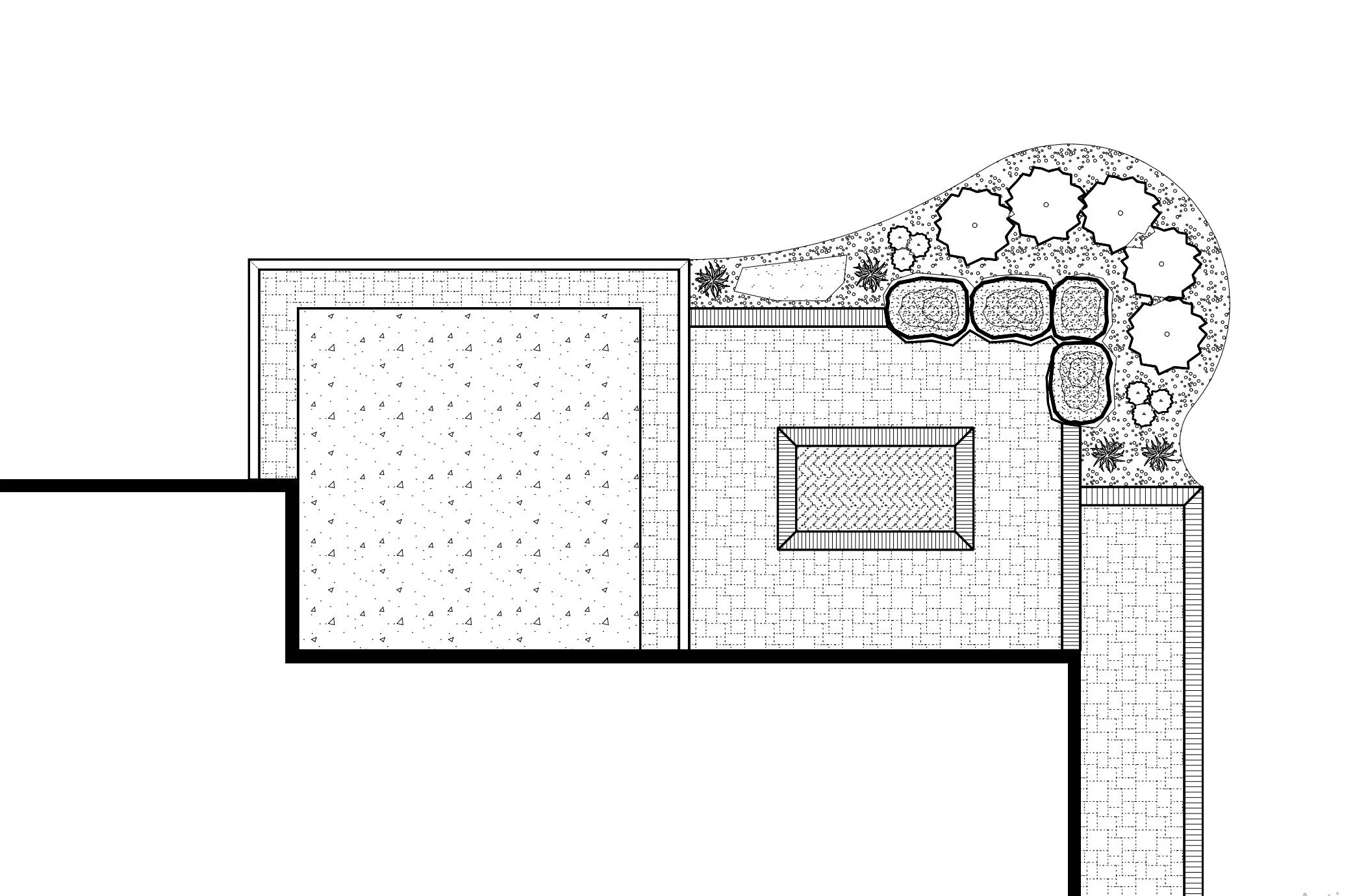

It All Begins With A Design

It all begins with a design. Nothing is more frustrating than not knowing exactly what you’re paying for or a contractor not accurately predicting the cost associated with your project and needing to come to you for significantly more money just to complete the job.

With a proper design, paired with site visits, we can completely avoid these frustrations. We are not only on the same page in regard to our scope of work but we can also accurately quote the project for you. This also allows us to properly prep the site for your project. Planning where materials and equipment will be staged, what areas of landscaping may be impacted, temporary drainage solutions, and of course physically drawing out the design onsite for you to “step into” before we break ground.

Whether we’re doing a full blown outdoor transformation or a simple patio, we strive for the entire process to be as smooth as possible!

Base Preparation

Ask any seasoned paver contractor and they’ll tell you base preparation is the key to a long lasting install. Just as a failure in the foundation of your home is going to cause serious issues, a failure in paver base will ruin what may have been a perfect install.

There are many considerations when planning for a proper base for pavers. These are some that we discuss and inspect while onsite in our consultations and design phase.

Surrounding Soil Type

Sub Base Percolation Rate

Sub Base Hardness

Paver Application

Elevations

Drainage

Existing and Future Landscaping

Our Standard Base

(From Top): Paver, Setting Bed, Base, Separation Fabric, Sub Grade (native soil).

As noted above, there are many considerations that may influence what is required for a paver base. But we do follow strict minimums on any paver project that we have outlined here.

We can break down everything beneath the pavers into three sections.

Sub-Grade

Base

Setting Bed

The sub-grade is the soil beneath our base material and the grade that we excavate to in order to accommodate for our base material, setting bed and paver depth. After careful excavation of soils, the sub-grade is ready to be prepared for base installation. Our preparation of the sub-grade goes above the standard practices to ensure your project is built to last. Or first step is an amendment to the soil. Instead of simply compacting the sub-grade soils we spread light layers of gravel that we then compact into the sub-grade soils. We repeat this process until the soils will no longer accept any more gravel. We have found that this amendment not only increases the bear capacity of the soil but also the sub-grades ability to remove water from base material by increasing the percolation rate. We then install separation fabric to ensure no soil migration into our base material, increase bearing capacity and further ensure no paver settlement. In some applications we also include a bi-axial high strength vehicle rated geo-grid when clients need the paver area to be able to handle heavy traffic (IE: Driveways & Parking).

The base is the foundation for our pavers. The minimum base we use is six inches in depth and six inches beyond all paver edges. Some contractors may claim four inches is sufficient, however the CMHA (Concrete Masonry Hardscape Association) show that inferior soil conditions require additional base material to be used. Because our native soils are clay (a poor draining and cohesive soil) we need to add an additional 2” of base material. When comparing quotes clients should take this into consideration. The material we use for our base is either DOT certified road base or washed #57 stone. We meticulously compact these material in lips of 2-3” until we have reached the appropriate depth of base material. The intended use of this area can also dictate the required base depth. IE: (areas for vehicular use require a minimum of twelve inches).

The setting bed is a one inch layer of small rock or concrete sand that is screeded in order to lay our pavers on a perfectly uniform surface and is also a key element in the interlocking properties of pavers.

-

Absolutely! Pavers are a perfect for your driveway. When the appropriate paver is installed correctly not only will you have a aesthetically superior surface to concrete or asphalt you’ll also have a driveway that will outlast any concrete or asphalt counterpart.

-

Look for contractors that specialize in paver installations. Ask about their standard installation practices and to see their portfolio. I also recommend taking a look at some catalogs to help get a gauge of quality work. Ask about certifications, warranties, licenses and insurance.

Southern Crafted Hardscapes is CMHA certified for both retaining wall and paver installation. Additionally we are an authorized contractor for Unilock. Our work has been featured numerous times and we strive for excellence in all of our installations. We love our craft and our typical clients are discerning individuals who value craftsmanship and integrity.

-

A failure in a paver surface could be caused by a number of reasons. Most commonly, a failure is caused by poor base installation practices. IE: (inadequate base material depth, poor or no sub grade preparation, poor compaction, etc.)

The second most common and will also be a side effect of a poor base is a loss on interlock with pavers. Similar to the pavers base there are a whole host of reasons why a paver surface may loose interlock due to poor installation practices. IE: (Poor edge restraint, inappropriate paver pattern for application, poor joint fill installation, etc.)

However when pavers are installed correctly at each step they are extremely resilient to shifting or settling and can be enjoyed for generations.